A work truck suspension needs to do three things: support the load, keep the truck stable, and soften the ride to protect the cargo, truck and driver. Of course, not all loads or routes are equal. That’s why it’s important to get the right type of suspension to meet the performance, cost and maintenance requirements for your truck. Cassone purchases and sells trucks with many different types of suspensions, we’ll find the right one for you.

Mechanical suspensions are mostly found on medium duty (Class 5-7) single axle trucks. Some of these trucks have leaf springs, while others use elastomeric springs made out of rubber. Elastomeric suspensions are more expensive up front, but offer a better ride than leaf spring mechanical suspensions. While these suspensions are inexpensive, they ride rougher than air suspensions. Rubber and leaf spring suspensions are also used on some Class 8 vocational trucks. Spending less on a suspension makes sense on vehicles that are rarely used on highways.

Air suspensions are standard on Class 8 trucks used on the highway, as well as medium duty trucks that haul sensitive cargo, like glass drink bottles. This type of suspension offers better control, improving performance at high speeds. Logging, oil field and heavy equipment trucks also use these suspensions because they’re regularly driven on both dirt and paved roads.

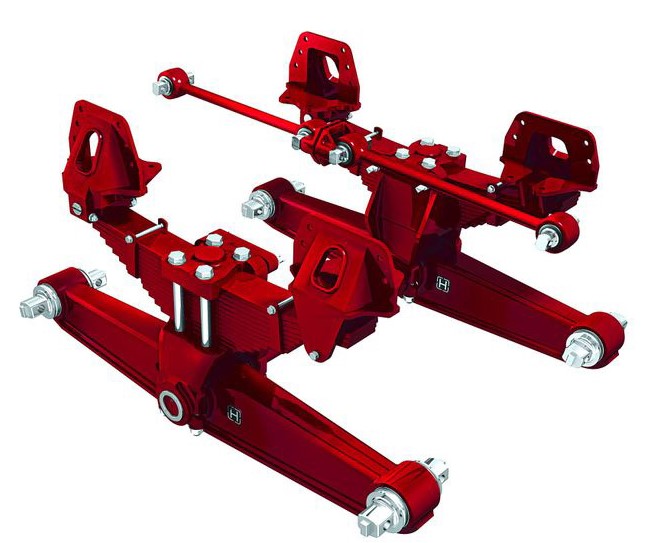

There are suspension structural components shared across all suspension designs. The axles need shocks to control the compression and release of the springs, while torque rods keep the axle in position, both left to right and front to back. These components must be designed to work well with one another to deliver a controlled ride and maintain reliability. Aftermarket components can cause problems because they don’t work with the suspension as a whole. While polyurethane is pitched as a superior, longer lasting alternative to rubber, it won’t perform like rubber. This can worsen the ride, and add strain on suspension structural components, leading to increased repairs over time.

No one suspension technology is superior. It’s just a matter of choosing what fits your use case. While leaf springs may seem cheaper than elastomeric suspensions at first glance, the improved ride quality can mean a much lower cost of ownership for a rubber suspension over the life of the vehicle. Likewise, while paying extra for air suspension may seem like a good move, it may not be worth dealing with extra maintenance on trucks used in severe driving environments.